Water Well Design

Brotcke Well & Pump Company, Inc., (BWP) is a full service design-construct, municipal and industrial water well and pump service contractor. For over 30 years, BWP has been providing water-related engineering and construction services to clients throughout the Midwest.

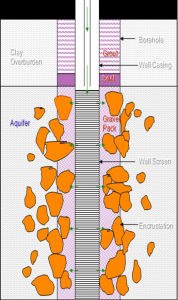

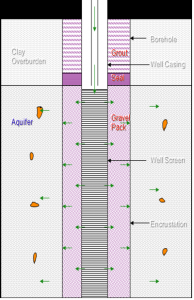

BWP performs design-construct services ranging from complete hydrologic engineering investigations to locate new water supply aquifers to the selection of water well rehabilitation procedures. We have installed both alluvial and consolidated water wells from small capacity wells to installations over 3200 GPM. We specialize in alluvial gravel wall wells with outside diameters ranging from 20 to 60 inches. When required, double gravel wall wells have been recommended and installed to provide an effective filter for very fine sand formations. Dependent on the requirements, both direct rotary and reverse rotary drilling techniques are utilized.Well design is based on intended use, desired capacity and the aquifer’s hydrologic properties.

One or more test borings are required to define the aquifer at the desired well location. Gradation tests of representative samples allow selection of well screen slot size and gravel pack. The right well screen coupled with the proper gravel pack results in a highly efficient, sand free well – our project goal.

Well screens and casing ranging from 8″ to 36″ are commonly used with bore hole diameters ranging from 24″ to 60″.

BWP specializes in reverse circulation drilling – the preferred method in unconsolidated formations because it minimizes drilling fluid additives, assuring a high-efficiency well.

CALL OR EMAIL FOR AN ESTIMATE TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Airshock

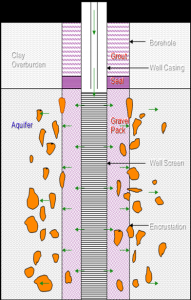

The AirShock® Impulse Generator (AIG) is the latest, environmentally-safe water well rehabilitation process. It uses bursts of compressed gas to remove build-up from well screens, gravel packs and surrounding aquifers. It provides a “green” alternative to water well rehabilitation and development because it uses fewer (if any) chemical additives.

GREEN TECHNOLOGY

AIG fires automatically once every 2-3 seconds and each burst lasts just several dozens of milliseconds. Resulting shock waves and powerful water surges, produced by this process, successfully remove incrustation in the well screen, gravel pack and surrounding aquifer. In a very short time, a well is completely restored to the highest level of efficiency. The method is unique both in success and ease of setup and operation.

80 – 120% WATER WELL RESTORATION

AIRSHOCK® Impulse Generator is:

- Safe, environmentally friendly

- Highly effective for both screened and open wells

- Relatively short procedure of a few hours

- Well downtime 1-2 days only

- Used independently or in combination with chemicals

- Reliable equipment with negligible maintenance through years

- Contractor-owned

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Reclaiming Efficiency

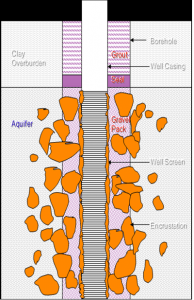

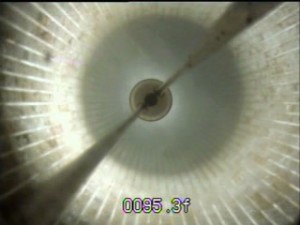

Over time, water wells become clogged and lose efficiency which directly relates to drinking water quality and quantity. Naturally occurring minerals precipitate out of solution as they enter the gravel pack and well screen of water wells. These minerals accumulate on the openings of the well screen and open spaces in the gravel pack, reducing the yield of the well. The precipitated minerals, along with oxygen introduced by the operation of the pump, cause an increase in biological activity, further reducing the yield of the well.

The environment in a water well is oxygen- and mineral-rich, ideal for bacteria to thrive and plugging to occur. If not cleaned, the gravel pack and well screens get clogged. The more clogged they get, the more costly it can be to rehabilitate a well. Left unattended, there is always the possibility of a system failure.

We won’t let that happen to you.

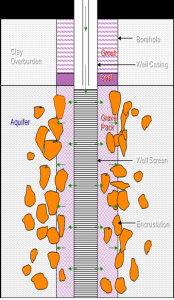

The Brotcke High Velocity Injection Process (U.S. Patent Number 5392814) is designed to clean this material mechanically by injecting a custom blend of chemicals at rates of up to 4,200 GPM with pressures of 60 PSI. By reversing the flow of fluid into the well at an extremely high rate, the loosened mineral and biological build up is removed from the well screen, gravel pack and native formation. Adding a custom blend of chemicals to the process achieves more effective cleaning by dissolving the mineral buildup and sequestering these materials so they can be removed from the well.

Our High Velocity Injection Technique has successfully rehabilitated hundreds of wells in the Midwest. Through this process, mineral deposits are removed from the formation as well as the well screen resulting in capacities much higher than those achieved by traditional methods of well cleaning.

Brotcke Well & Pump, Inc. (BWP) uses a patented High Velocity Injection Treatment process. It is a unique technique designed by BWP. A custom blend of chemicals engineered to meet each well’s specific requirements is injected and surged into the well and forced out into the formation.

All chemicals used by BWP are National Sanitary Foundation (NSF) approved.

Click the movie above to see the difference.

Our patented treatment system is designed to:

- clean the well screen with a combination of pressure and chemistry

- dissolve and remove build up

- sterilize the well environment

- improve flow capacity

CALL OR EMAIL FOR AN INSPECTION TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services