Hydrological Investigation

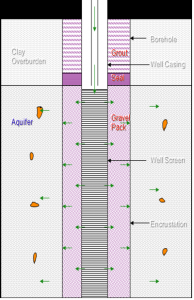

Engineering water wells begins with a thorough understanding of the aquifer. Test holes are necessary to determine the aquifers integrity and locate an acceptable location for the new well. A location which has the following properties is highly desirable:

- Saturated Thickness – High

- Relative Density – Low

- Coarseness of the Sand – High

- Amount of Fines in the STRATUM – Low

From a single well to an entire field – BWP’s capabilities and track record speak for themselves. We provide our clients the data and analysis that allows them to make confident decisions.

A Hydrologic Engineering Study is approached as a multi-phase project at Brotcke Well & Pump, Inc. While there can be many variations from project to project, our approach is as follows:

- PHASE 1 Test Boring Program

- PHASE 2 Laboratory Sieve Analysis

- PHASE 3 Test Well Construction and Pump Testing

- PHASE 4 Engineering Analysis and Report

LOCATING NEW SOURCES OF GROUND WATER FOR OVER 35 YEARS

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Reclaiming Efficiency

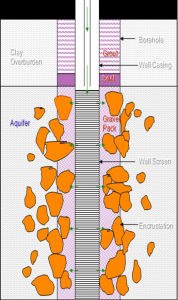

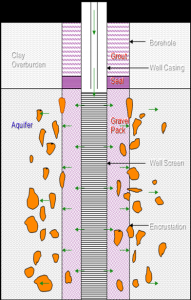

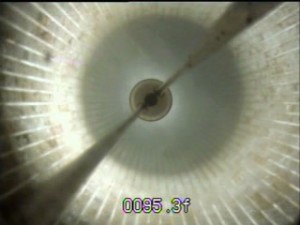

Over time, water wells become clogged and lose efficiency which directly relates to drinking water quality and quantity. Naturally occurring minerals precipitate out of solution as they enter the gravel pack and well screen of water wells. These minerals accumulate on the openings of the well screen and open spaces in the gravel pack, reducing the yield of the well. The precipitated minerals, along with oxygen introduced by the operation of the pump, cause an increase in biological activity, further reducing the yield of the well.

The environment in a water well is oxygen- and mineral-rich, ideal for bacteria to thrive and plugging to occur. If not cleaned, the gravel pack and well screens get clogged. The more clogged they get, the more costly it can be to rehabilitate a well. Left unattended, there is always the possibility of a system failure.

We won’t let that happen to you.

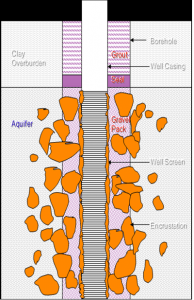

The Brotcke High Velocity Injection Process (U.S. Patent Number 5392814) is designed to clean this material mechanically by injecting a custom blend of chemicals at rates of up to 4,200 GPM with pressures of 60 PSI. By reversing the flow of fluid into the well at an extremely high rate, the loosened mineral and biological build up is removed from the well screen, gravel pack and native formation. Adding a custom blend of chemicals to the process achieves more effective cleaning by dissolving the mineral buildup and sequestering these materials so they can be removed from the well.

Our High Velocity Injection Technique has successfully rehabilitated hundreds of wells in the Midwest. Through this process, mineral deposits are removed from the formation as well as the well screen resulting in capacities much higher than those achieved by traditional methods of well cleaning.

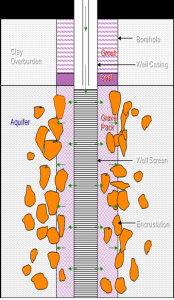

Brotcke Well & Pump, Inc. (BWP) uses a patented High Velocity Injection Treatment process. It is a unique technique designed by BWP. A custom blend of chemicals engineered to meet each well’s specific requirements is injected and surged into the well and forced out into the formation.

All chemicals used by BWP are National Sanitary Foundation (NSF) approved.

Click the movie above to see the difference.

Our patented treatment system is designed to:

- clean the well screen with a combination of pressure and chemistry

- dissolve and remove build up

- sterilize the well environment

- improve flow capacity

CALL OR EMAIL FOR AN INSPECTION TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services